Navigating Quality Assurance: A Deep Dive into Clothing Manufacturing Standards

kno01062023-05

In the vast and ever-changing landscape of fashion, maintaining unwavering quality standards in garment manufacturing plays a pivotal role. As a leading clothing manufacturer, D&J is deeply committed to upholding the highest benchmarks of manufacturing excellence, delivering top-quality garments to our fashion design clients.

For emerging clothing brands, understanding the nuances of quality assurance and the methodologies behind it is crucial. Furthermore, it’s also critical to comprehend how to assess a potential garment manufacturer’s compliance with your quality expectations.

1. Understanding Quality Standards

Quality standards refer to the specific criteria that a product must meet to ensure it serves its intended purpose. In the realm of garment manufacturing, these standards may range from fabric quality, precision in stitching, and durability, to the overall finish of the product. At D&J, we adhere strictly to both international and in-house quality standards, ensuring that each product meets or surpasses the set criteria.

2. Quality Assurance in the Design Phase

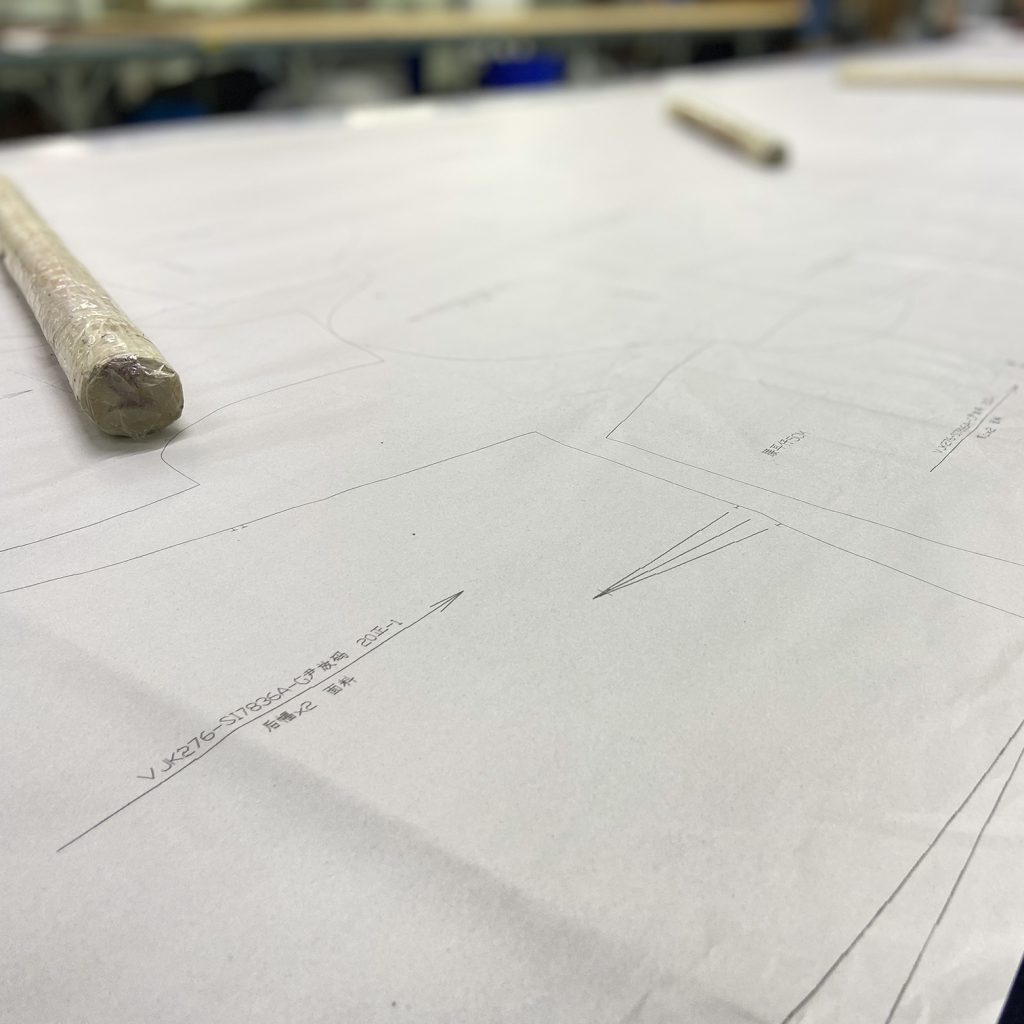

The design phase is instrumental in laying down the quality foundation of the final product. At D&J, we collaborate closely with our custom clothing brands to understand their design aesthetics and quality benchmarks. Our experienced design team anticipates potential quality issues right at the design stage, such as by choosing high-quality fabrics that best complement the specific design.

3. Quality Control during the Manufacturing Process

Quality control during the manufacturing phase is paramount. Our dedicated QC team conducts thorough inspections at key stages of production, including cutting, stitching, assembling, and packaging. These checks ensure the conformity of each garment to the design specifications, and any deviations are promptly corrected.

4. Final Product Inspection

Upon completion of the manufacturing process (Surviving Fashion: The Major Hurdles for Garment Manufacturers), a final product inspection is conducted. This step ensures that every piece aligns with the design, size, and quality parameters set forth by our clients. At D&J, our quality inspectors use sophisticated tools and techniques to ensure precision and consistency across batches.

5. Quality Feedback and Continuous Improvement

Post-production, we actively seek feedback from our clients to understand their level of satisfaction with our product quality and service. This feedback loop allows us to continually refine our processes, enhancing our ability to deliver excellent products.

As a reputable clothing manufacturer, D&J is dedicated to crafting high-quality custom clothing. By integrating our specialist knowledge with our unwavering commitment to quality, we aim to help your brand succeed in the competitive world of fashion.

Google: D&J Fashion Manufacturer

Leave us a Google Review

Facebook: dnjfashionofficial

Instagram: dnj_fashion_official

Linkedin: D&J Garment Manufacturing and Supply Chain

Pinterest: dnjfashion

Youtube: @dnjfashion_official

Tik Tok: @dnj_fashion