How D&J Fashion Helps Global Brands Achieve Scalable and Sustainable Profitability

In a fashion landscape increasingly defined by speed, margin pressure, and global volatility, apparel profitability now hinges on more than just strong sales or trend-right collections. It demands operational precision.

At D&J Fashion, a seasoned women’s fashion manufacturer with over 22 years of experience in OEM and ODM production, we partner with brands across North America, Europe, and Asia to build production systems that are lean, responsive, and profitable—without sacrificing product quality or creativity.

Why Production Efficiency Matters More Than Ever

According to McKinsey & Company’s 2023 “State of Fashion” report, the apparel sector continues to face rising input costs, with raw materials up 20–30% from 2019 levels in some categories, and compressed lead times due to demand for near-instant product drops and re-stocking.

Brands that fail to adapt risk margin erosion, inconsistent delivery, and costly returns.

Meanwhile, Coresight Research reports that 24.4% of online apparel purchases are returned—largely due to fit, quality, or inconsistencies caused by suboptimal production and QC processes. Efficient, predictable manufacturing reduces these downstream costs.

Key Advantages of an Optimized Production System

✔️ Lower Per-Unit Cost

✔️ Faster Time-to-Market

✔️ Consistent Quality & Lower Return Rates

✔️ Better Margin Protection During Market Volatility

In short: Efficient production is profit protection.

Five Practical Strategies D&J Fashion Uses to Improve Production Profitability

1. Production Layout Optimization

We conduct line balancing and time-motion analysis to identify bottlenecks and improve station layout.

In one recent European brand project, this allowed a 12% increase in daily output—with no additional labor or equipment investment.

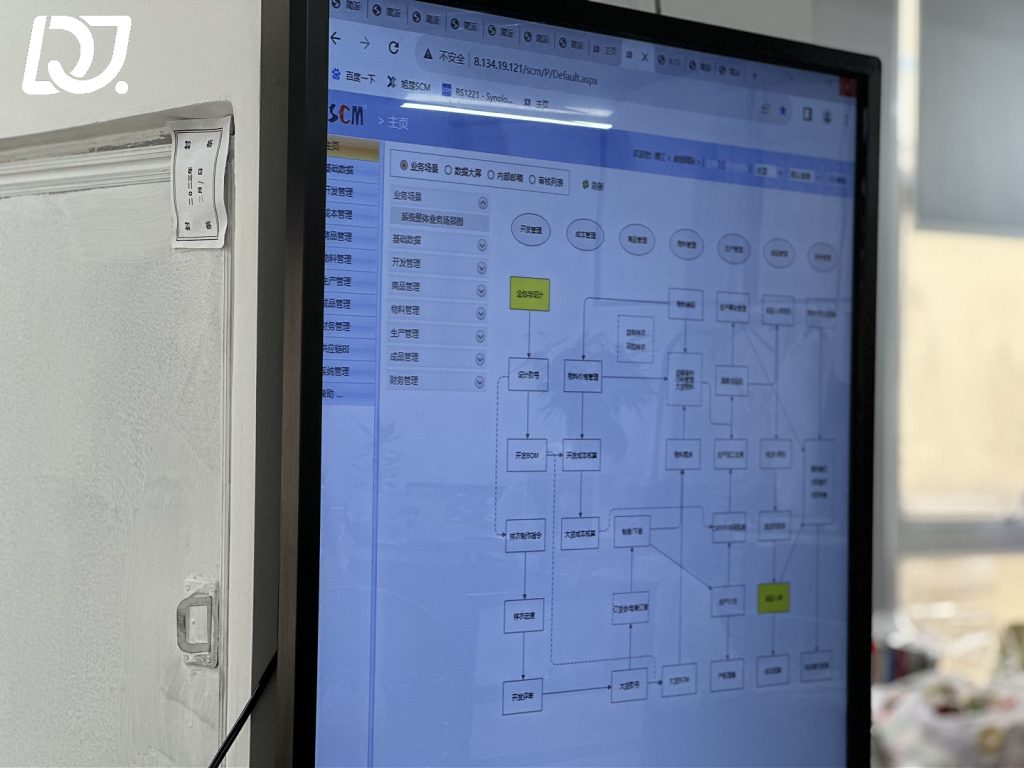

2. Real-Time Production Tracking

Using integrated MES (Manufacturing Execution Systems) and digital dashboards, we help clients track WIP (work-in-progress), error rates, and production timelines.

This allows rapid issue resolution and smoother order planning for wholesale and DTC channels.

3. Strategic Fabric & Trim Sourcing

We negotiate long-term agreements with verified textile mills, enabling:

- 8–15% cost savings on core fabrics

- Better MOQ flexibility for small-batch capsule drops

- Shorter lead times on replenishment runs

4. Waste Reduction Through Automation

With computer-controlled cutting machines and optimized lay plans, we minimize fabric waste—sometimes by up to 20% depending on fabric type.

We also help clients implement zero-waste initiatives (e.g., upcycled trims, accessories from offcuts).

5. Workforce Training & Incentive Systems

At D&J, we treat our people as core assets. We provide:

- Monthly training sessions on quality control, lean practices, and teamwork

- Zero-defect reward programs by team

This directly reduces rework rates and boosts morale.

How It All Comes Together: The D&J Difference

At D&J Fashion, we don’t just manufacture garments—we build efficient, scalable systems that power long-term brand growth. From capsule collections to high-volume wholesale production, our global partners trust us to:

- Deliver consistent quality at scale

- Improve production speed without sacrificing craftsmanship

- Reduce cost leakage across sourcing, cutting, and QC

- Provide data-driven insights for better forecasting and margin control

🧵 Whether you’re launching a new collection or scaling a best-seller, our experienced team is here to help you build a smarter, more profitable apparel supply chain.

📩 Let’s talk about how D&J Fashion can support your production goals : [email protected]

kno082025-02

Google: D&J Fashion Manufacturer

Leave us a Google Review

Facebook: dnjfashionofficial

Instagram: dnj_fashion_official

Linkedin: D&J Garment Manufacturing and Supply Chain

Pinterest: dnjfashion

Youtube: @dnjfashion_official

Tik Tok: @dnj_fashion