Why 3D Virtual Sampling is the Future for Your Clothing Manufacturing Business

blo01072023-04

Are you a retail brand or a fashion house looking for innovative ways to streamline your production process and boost your profits? If so, partnering with an apparel manufacturer that utilizes 3D digital design and sampling could be the game-changer you’ve been waiting for. This innovative approach is revolutionizing the apparel manufacturing industry, offering a cost-effective and sustainable solution for brands of all sizes.

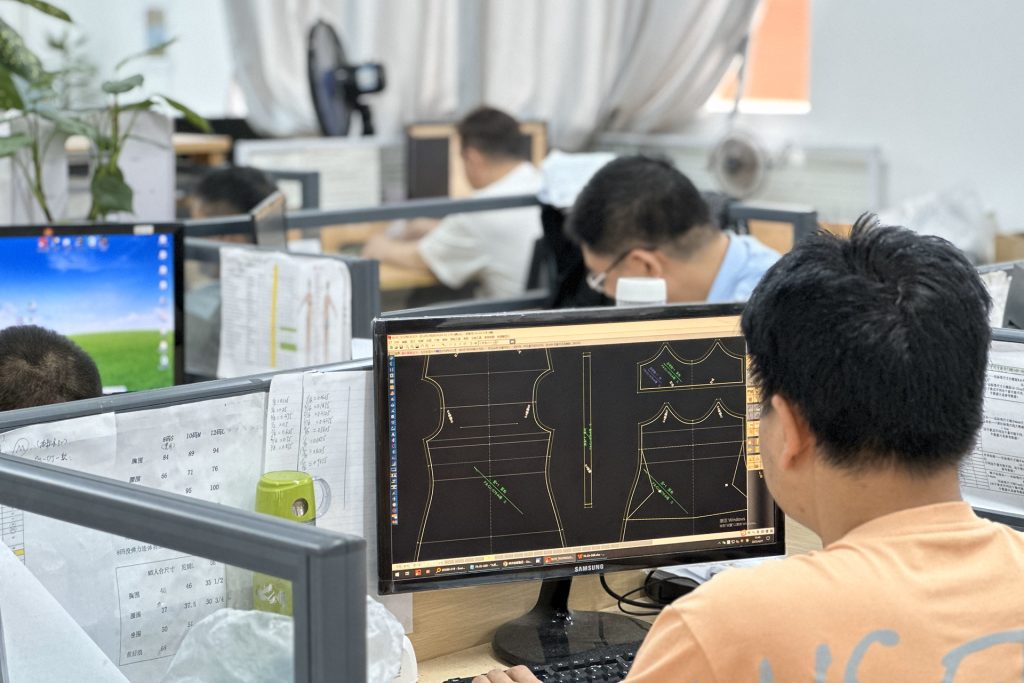

The Rise of 3D Digital Design in Apparel Manufacturing

The apparel manufacturing industry is rapidly embracing 3D digital design. This technology is becoming an essential tool for manufacturers aiming to enhance their sustainability and circularity commitments. By going digital, manufacturers can significantly reduce their physical sampling costs, contributing to the development of a circular fashion economy.

The Power of 3D Digital Samples in Apparel Manufacturing

Initially, the apparel manufacturing industry was skeptical about the feasibility of 3D photorealistic digital models. However, these digital samples have proven to be incredibly versatile, reducing physical sampling by at least 30%. They can be used in various aspects of the business, including catalogs, tradeshows, virtual showrooms, social media, and stakeholder surveys.

By reducing textile waste in the supply chain and decreasing manufacturing lead times, 3D digital design can significantly improve a manufacturer’s sustainability and economic performance.

The Future of Apparel Manufacturing: 3D Digital Sampling

The adoption of 3D digital sampling is inevitable as the apparel manufacturing industry evolves. For brands interested in saving money, and time, and contributing to climate change mitigation, partnering with a manufacturer that utilizes this technology is a no-brainer.

The Benefits of Partnering with a 3D Digital Sampling Manufacturer

-Reduces the number of physical samples by 60%

-Cuts development and design time by 35%

-Decreases fitting sessions by 40-50%

-Enhances communication between your brand and the manufacturer

-Eliminates the need for transporting samples from country to country, saving fuel and reducing CO2 emissions

-Reduces water use, chemical waste, and energy consumption

-This prevents physical samples from ending up in landfills or incinerators

In conclusion, 3D digital design offers a more efficient and sustainable way of designing and prototyping clothing. It’s an essential tool for the future of apparel manufacturing.

Google: D&J Fashion Manufacturer

Leave us a Google Review

Facebook: dnjfashionofficial

Instagram: dnj_fashion_official

Linkedin: D&J Garment Manufacturing and Supply Chain

Pinterest: dnjfashion

Youtube: @dnjfashion_official

Tik Tok: @dnj_fashion