Tips on How to Work With Your Fashion Manufacturer

Photo: Pexels

blo01012023-03

Working effectively with your fashion manufacturer is crucial to the success of your clothing line. By staying organized, communicating clearly, being open to feedback, and establishing realistic timelines, you can build a strong partnership with your clothing manufacturer. This collaborative approach will help bring your unique vision to life and pave the way for a thriving fashion business.

Photo: Pexels

Stay Organized and Communicate Effectively

Organization is key when working with a clothing manufacturer. Ensure you have clear documentation for each design, including technical drawings, fabric requirements, sizing information, and any specific production details. This will help prevent misunderstandings and ensure a smooth production process. Maintain open and honest communication with your manufacturer, addressing any questions or concerns promptly.

Photo: Pexels

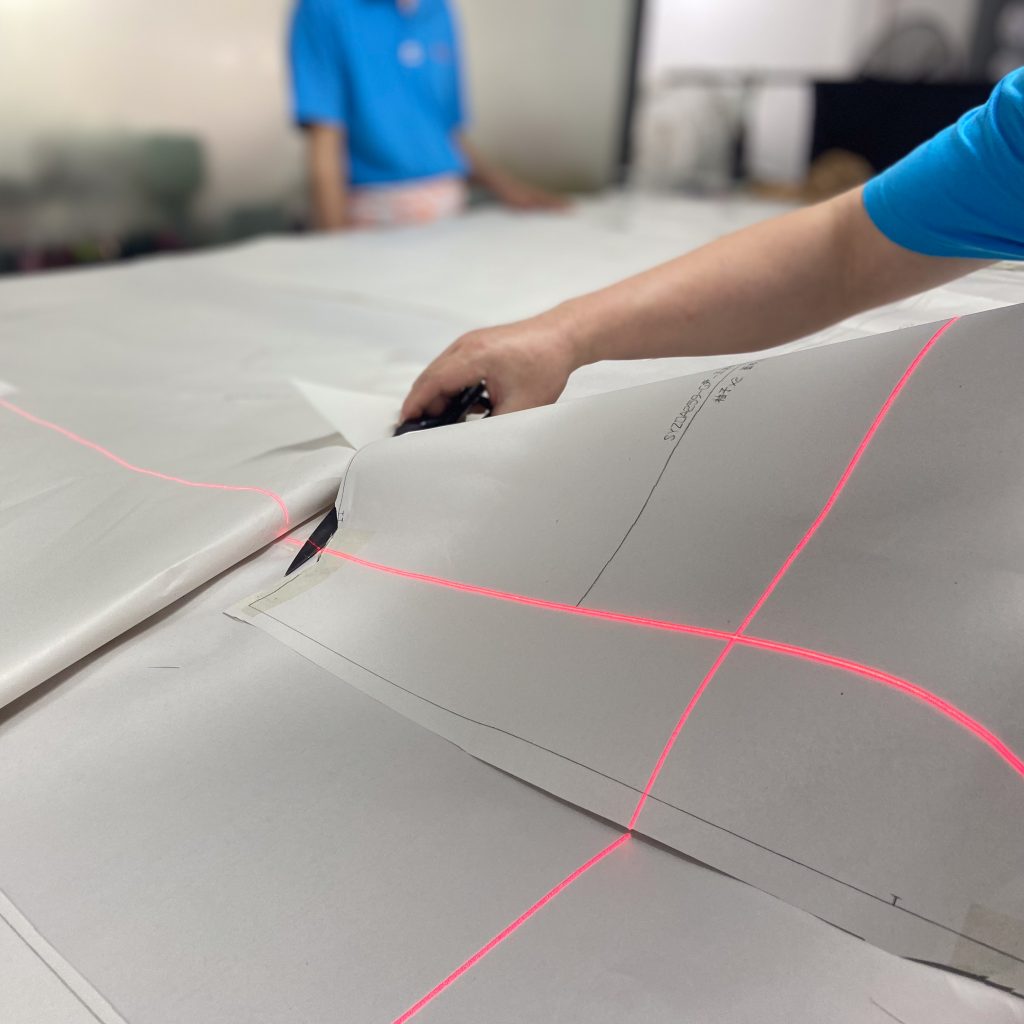

Present Your Ideas Clearly and Precisely

When discussing your design ideas with your fashion manufacturer, it’s essential to be as clear and precise as possible. Use visual aids such as sketches, mood boards, or digital renderings to help convey your vision. This will minimize the risk of misinterpretations and help your manufacturer understand your creative direction.

Photo: Pexels

Be Open to Feedback and Listen to Your Manufacturer’s Expertise

Your clothing manufacturer is an experienced professional, so it’s crucial to value their expertise and be open to their feedback. They may offer suggestions on improving your designs, selecting materials, or streamlining the production process. By listening to their advice, you can refine your ideas and create a better final product.

Photo: Pexels

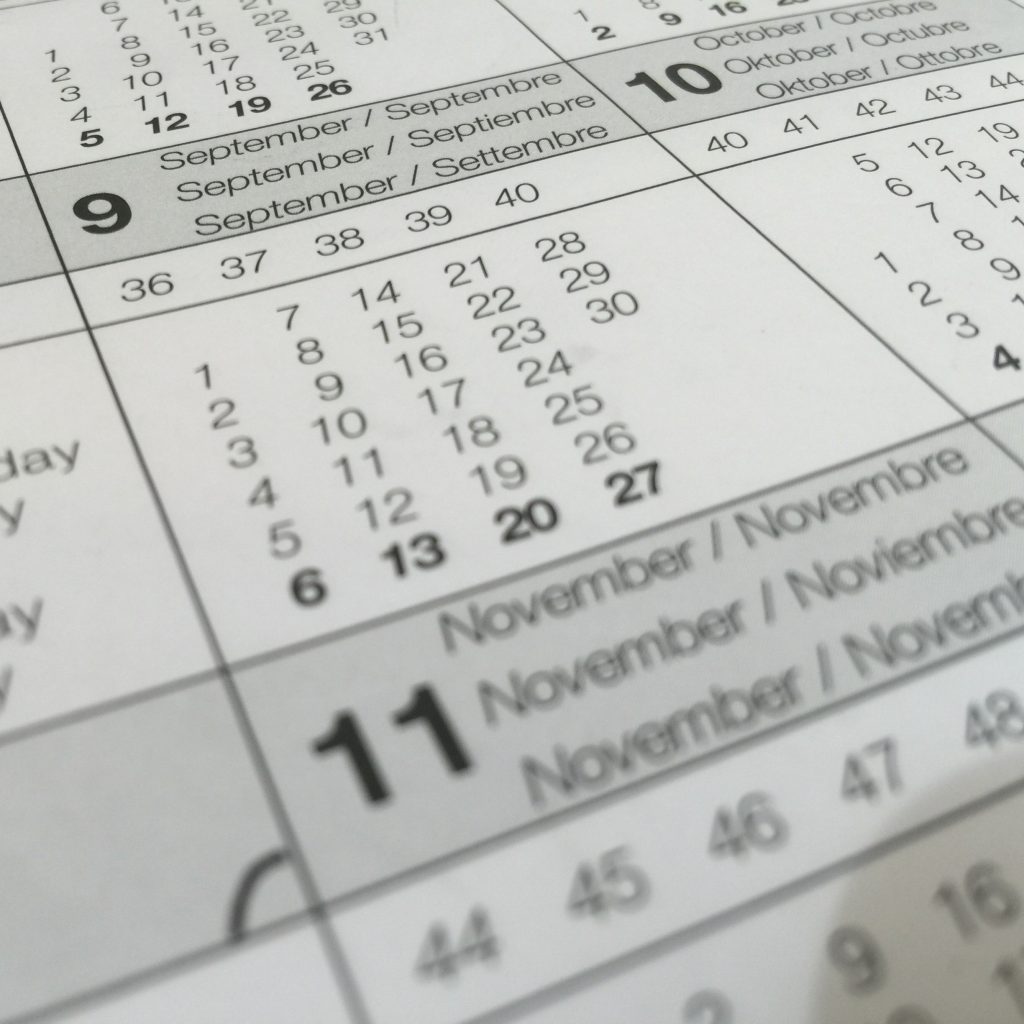

Establish Realistic Timelines and Deadlines

When working with a fashion manufacturer, it’s essential to set realistic timelines and deadlines for the production process. Discuss your desired production schedule and consider their input on what is feasible. Remember to factor in time for sampling, adjustments, and shipping to ensure you meet your launch or delivery dates.

Be Prepared for the Sampling Process

The sampling process is a critical stage in working with a clothing manufacturer. Be prepared to provide feedback on your samples, request adjustments, and work closely with your manufacturer to finalize your designs. Keep in mind that this process may require multiple iterations, so allocate sufficient time and budget accordingly.

Photo: Pexels

Maintain a Positive, Professional Relationship

A successful partnership with your fashion manufacturer is built on mutual trust and respect. Treat your manufacturer as a valuable member of your team and maintain a positive, professional relationship. This will encourage open communication, facilitate problem-solving, and contribute to your business’s overall success