The Art of Garment Manufacturing: Efficient Fashion Sampling

blo01072023-03

The fashion sampling process is an indispensable component of the pre-production phase in garment manufacturing. It serves as the quality determinant for buyers and a cost and time estimation tool for apparel manufacturers. A well-crafted sample enables buyers to assess a product’s quality before launching bulk production. Simultaneously, it provides clothing manufacturers with an estimate of the necessary resources for efficient and cost-effective garment production.

Before initiating the sampling process, there are key considerations that can significantly impact the efficiency of clothing production.

Budget Planning

The first step in the process involves setting a budget. Your budget will determine the number of sampling rounds you can afford, making it a crucial component of the garment manufacturing process. A well-planned budget can prevent unnecessary expenditures, saving valuable resources in the long run.

Product Design Focus

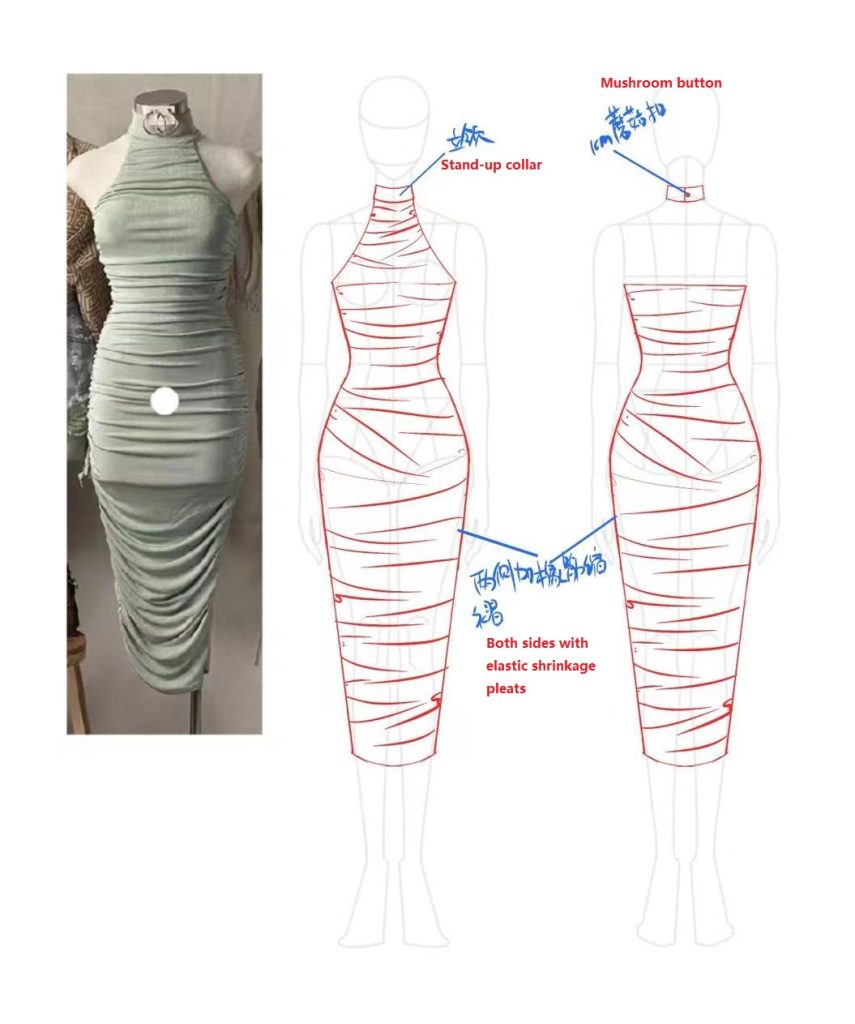

The journey of apparel manufacturing begins with a sketch. Even without artistic skills, the goal is to bring your ideas to paper to minimize future modifications during garment production. Moreover, understanding your sample size’s specifications will assist in establishing your product’s basic specs. Comprehending how your garment’s attributes such as stretch, thickness, and drape are influenced by the fabric used is also beneficial.

Reverse Engineering

Establishing a timeline and adhering to it is essential. Given the numerous elements involved in the fashion production process, working backward from your deadline aids in keeping your production schedule on track. Begin with the final step in your timeline and work backward from there, ensuring that your supplier is informed about the deadlines of your product launch plan.

Expert Collaboration

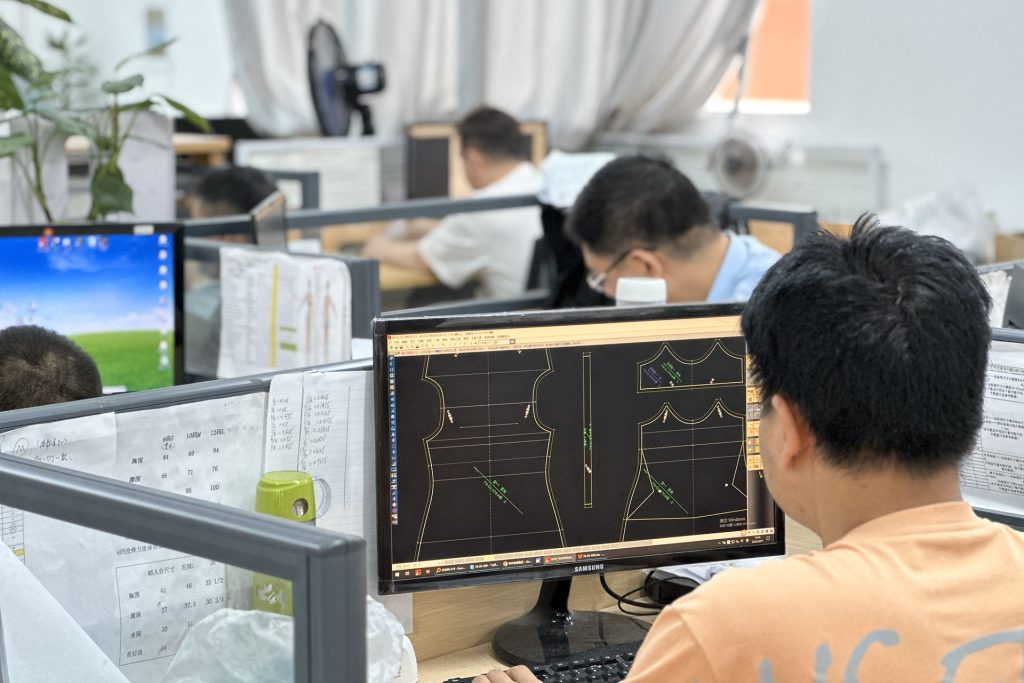

After finalizing your product sketch, the next step in fashion production is creating a blueprint. Working with a professional, such as a Patternmaker or Technical Designer, is vital to ensure your design is well-constructed before the onset of product development. Patterns contribute to product quality control, while Technical Designers create informative sheets that communicate your product requirements to manufacturers.

The number of samples you’ll need largely depends on the level of detail and planning put in at the beginning of the process. With proper planning and a clear budget, up to 12 samples might be needed. However, not all samples are essential. Typically, samples can be categorized into three major groups: Fit, Sales, and Production.

A common misconception among designers is that sampling costs should be absorbed by the supplier under marketing expenses. However, paying for samples is a part of the business, acting as an assurance to the supplier of the buyer’s seriousness. In certain scenarios, suppliers may offer free samples for established brands or previous clients, but for new clients and unknown brands, they will continue to charge to verify the client’s commitment to production.

Lastly, collaborating with a supplier or manufacturer with an in-house sampling team is an added advantage. This collaboration can facilitate the development of an affordable and high-quality sample, building credibility and saving time and cost. The fashion sampling process may seem complex, but with meticulous planning and attention to detail, you can successfully navigate it to bring your designs to life.

Google: D&J Fashion Manufacturer

Leave us a Google Review

Facebook: dnjfashionofficial

Instagram: dnj_fashion_official

Linkedin: D&J Garment Manufacturing and Supply Chain

Pinterest: dnjfashion

Youtube: @dnjfashion_official

Tik Tok: @dnj_fashion