Unlocking Creativity: The Art of Pattern Making in Custom Clothing

kno01072023-04

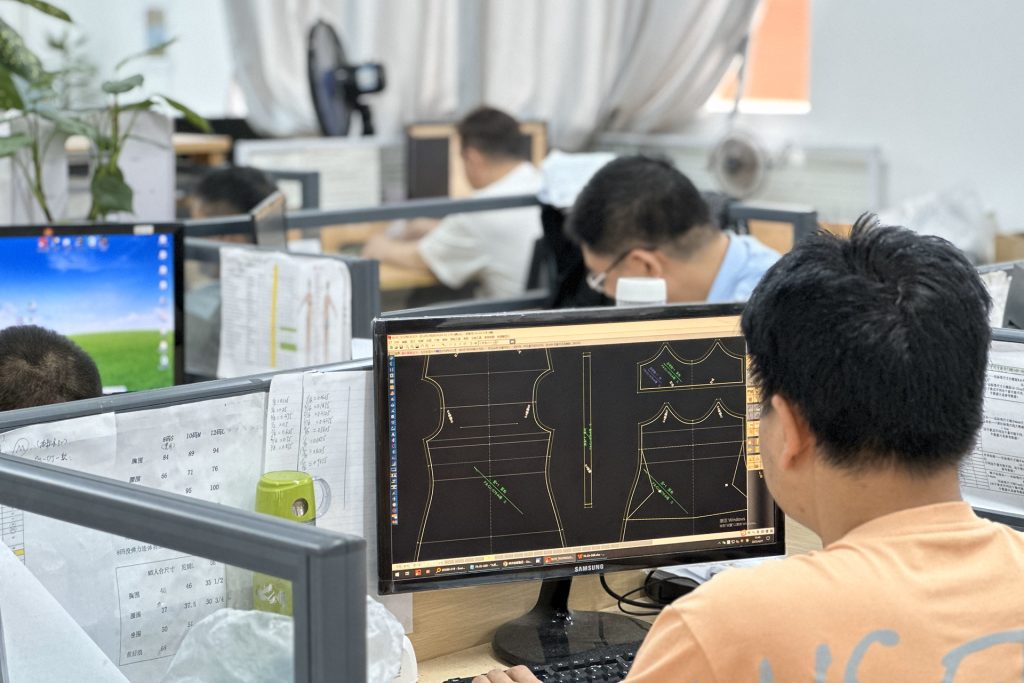

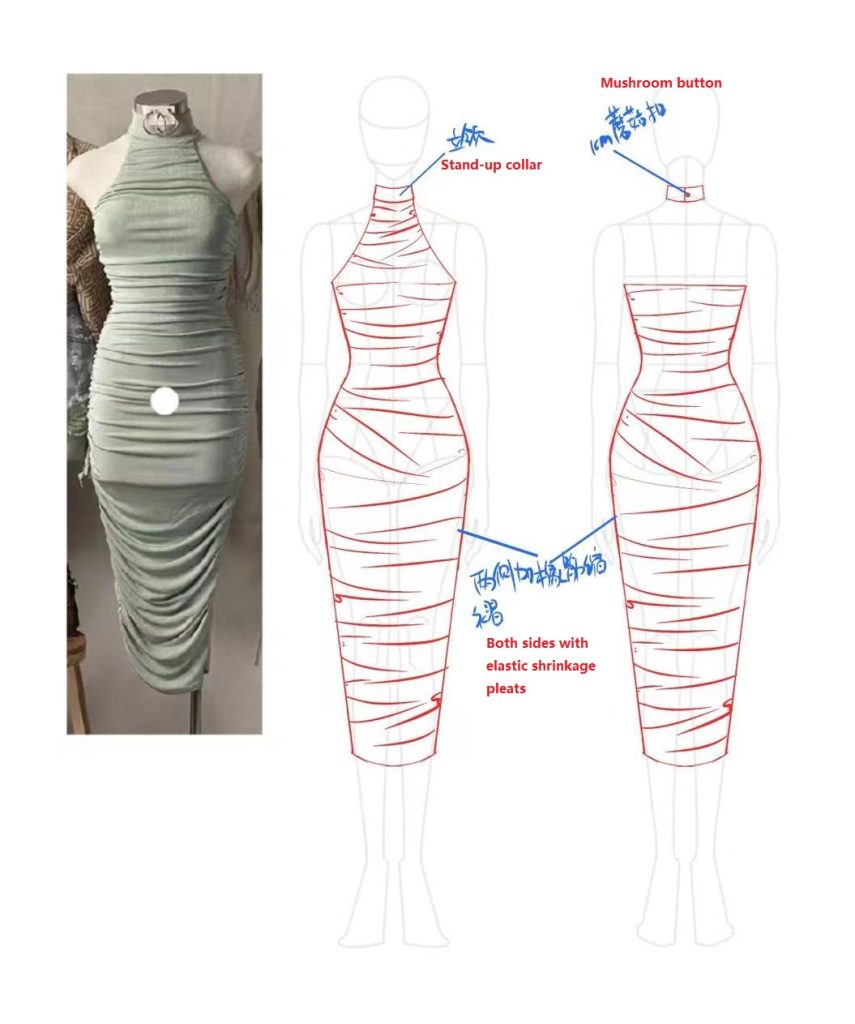

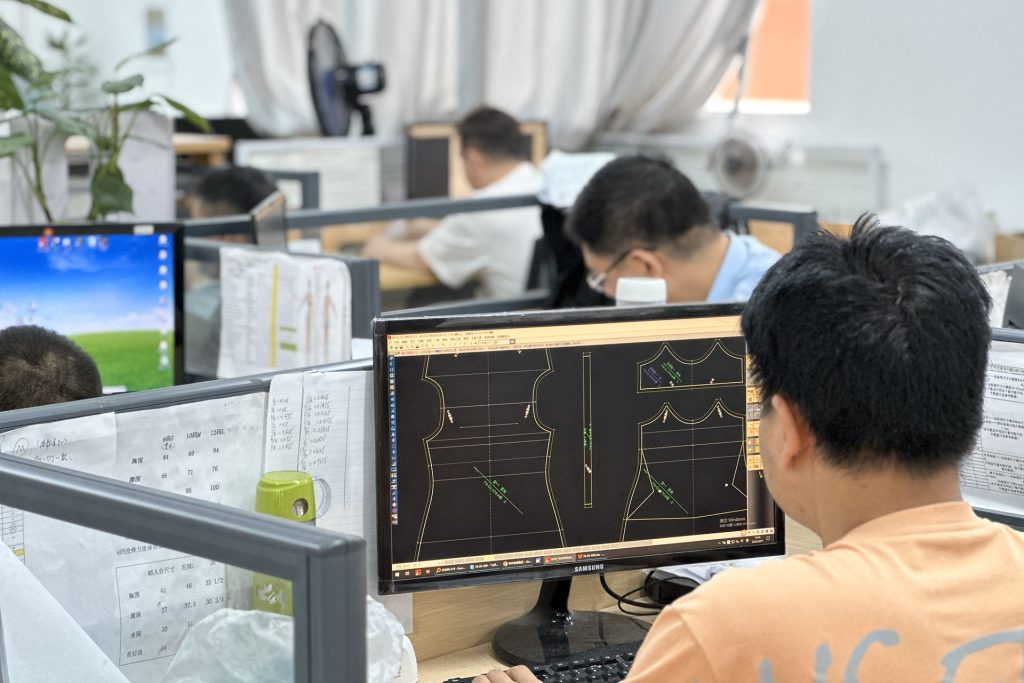

Pattern-making is a vital step in the manufacturing process of custom clothing. It involves the skilled craftsmanship of pattern makers who transform the creative visions of designers into tangible blueprints that guide the production of unique garments. Let’s explore the significance of pattern making and the technical expertise required to excel in this art form.

Importance of Pattern Making:

Pattern-making plays a pivotal role in the world of custom clothing. It serves as the bridge between a designer’s vision and the final product. By translating design concepts into precise patterns, pattern makers ensure accurate and consistent garment construction, ensuring the perfect fit for each wearer.

Technical Expertise of Pattern Makers:

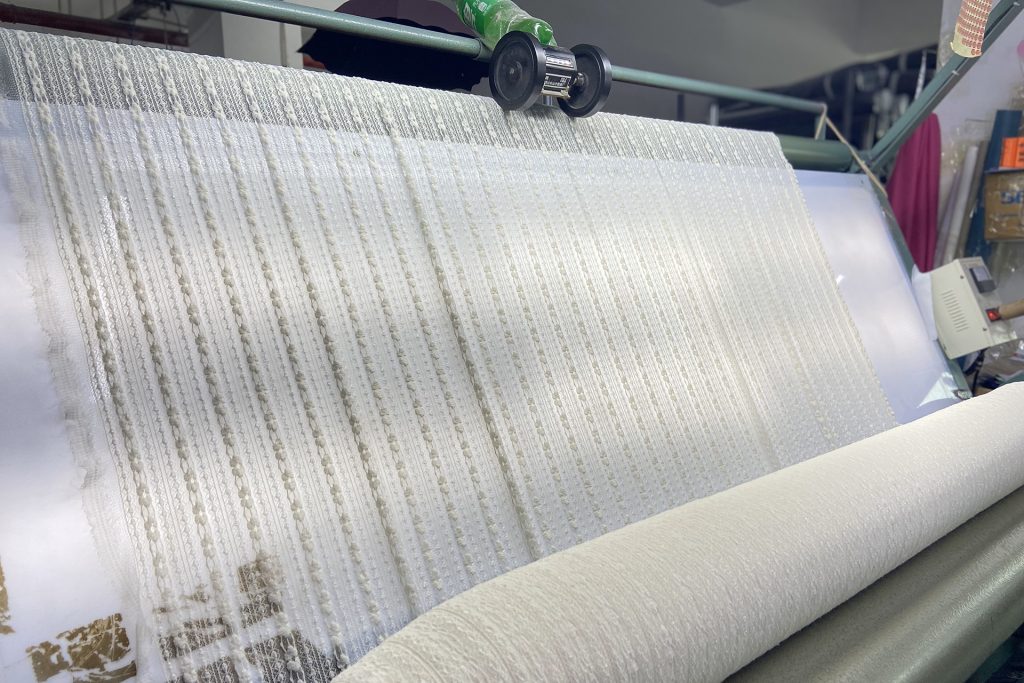

Pattern makers are highly skilled professionals with expertise in garment construction, pattern development, and sizing systems. They possess a deep understanding of how various fabric types drape and behave, allowing them to create patterns that optimize the fabric’s potential. Pattern makers work closely with designers to interpret their sketches and translate them into three-dimensional forms.

Technical Expertise of Pattern Makers:

Pattern makers are highly skilled professionals with expertise in garment construction, pattern development, and sizing systems. They possess a deep understanding of how various fabric types drape and behave, allowing them to create patterns that optimize the fabric’s potential. Pattern makers work closely with designers to interpret their sketches and translate them into three-dimensional forms.

The Pattern-Making Process:

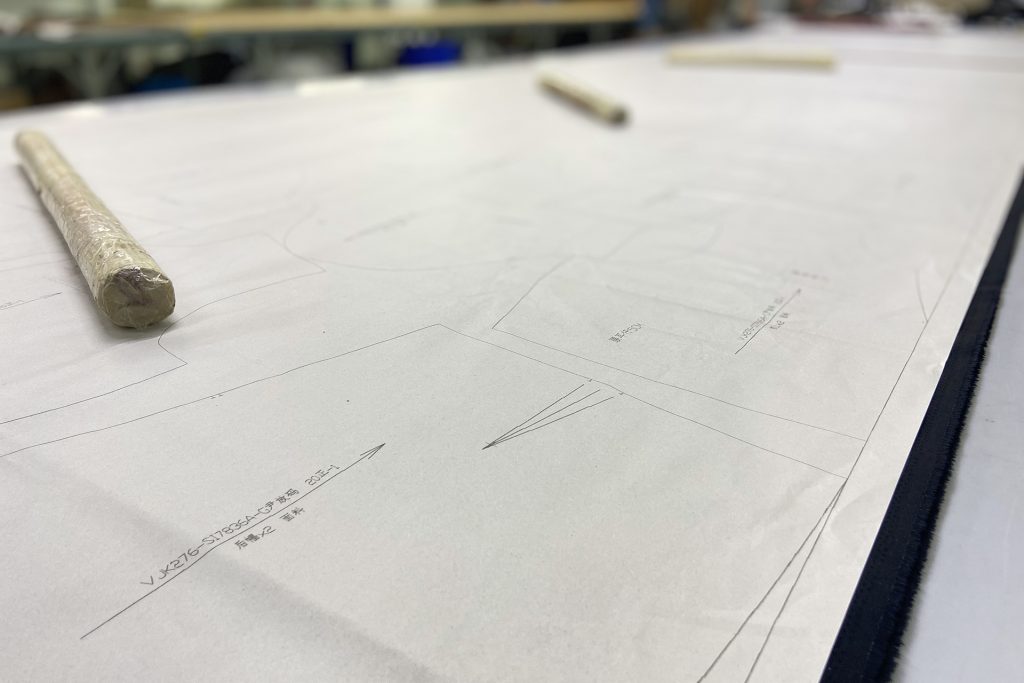

Measurements and Drafting: Pattern makers meticulously take measurements and use them as a basis for drafting the initial pattern. They consider factors such as ease allowances and garment style to ensure the desired fit and comfort.

Prototyping and Fit Sessions: Once the initial pattern is drafted, pattern makers create prototypes to test the fit and make necessary adjustments. Fit sessions with models or dress forms provide valuable feedback for refining the pattern.

Grading and Marker Making: Grading involves scaling the pattern to different sizes, ensuring consistency across the size range. Marker making involves creating layout templates for efficient fabric cutting.

Adaptation and Customization: Pattern makers often adapt existing patterns to suit specific design variations or customize patterns based on individual client measurements, ensuring personalized fit and style.

The Intersection of Art and Science:

Pattern-making is a harmonious blend of artistic creativity and technical precision. Pattern makers not only need an eye for aesthetics but also a deep understanding of garment construction techniques, fabric properties, and production processes. They must balance design intent with functional considerations to create patterns that bring fashion concepts to life.

Google: D&J Fashion Manufacturer

Leave us a Google Review

Facebook: dnjfashionofficial

Instagram: dnj_fashion_official

Linkedin: D&J Garment Manufacturing and Supply Chain

Pinterest: dnjfashion

Youtube: @dnjfashion_official

Tik Tok: @dnj_fashion